Products and Services

Custom Made Diamond/CBN Tool Types:

We offer a wide range of custom made tools. Since most tooling requires some type of customization, your application will define its design. Listed below are just some of the types of tools we offer. You can always share your application or concept with our engineers to design the perfect tool for you.

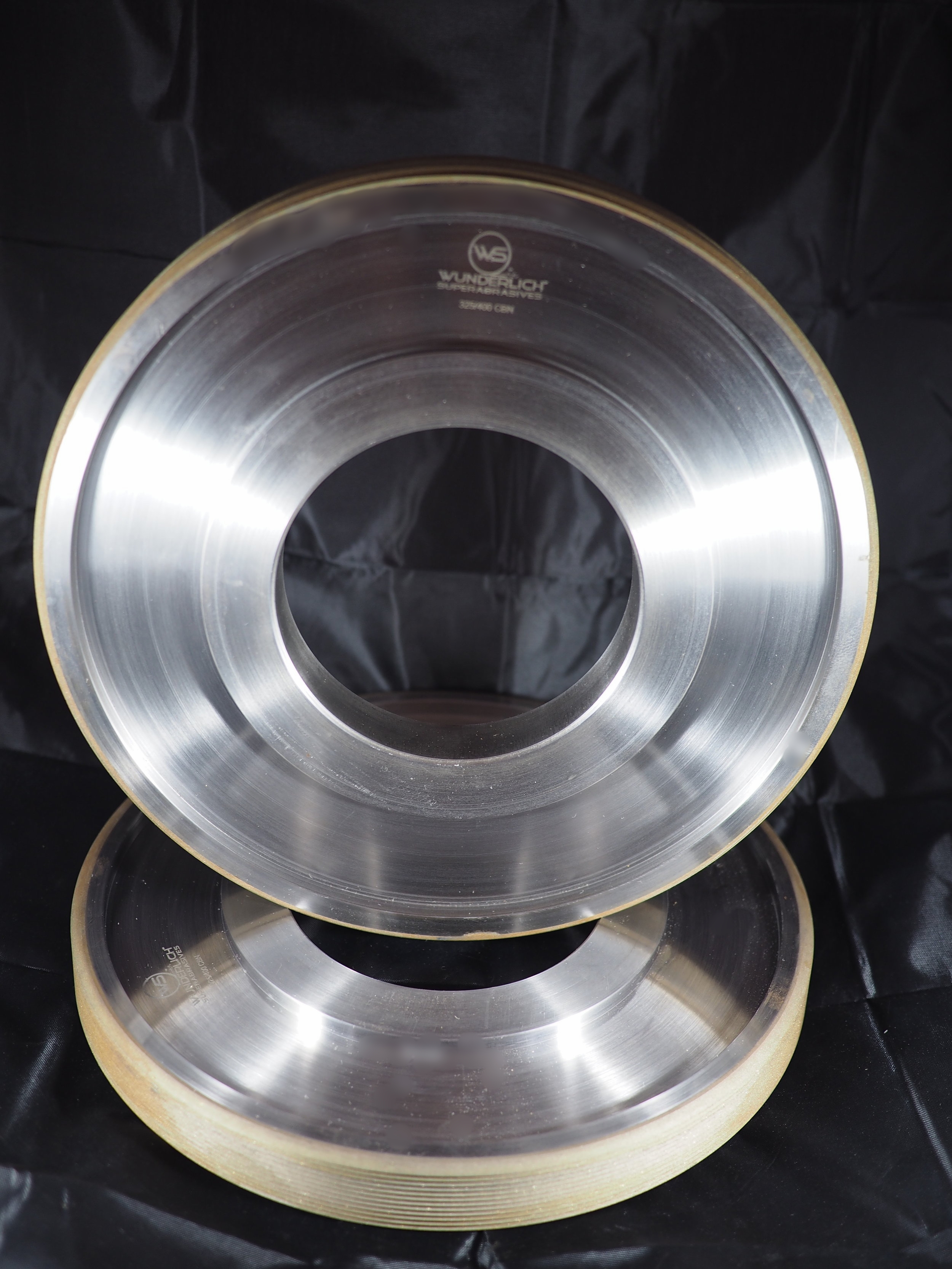

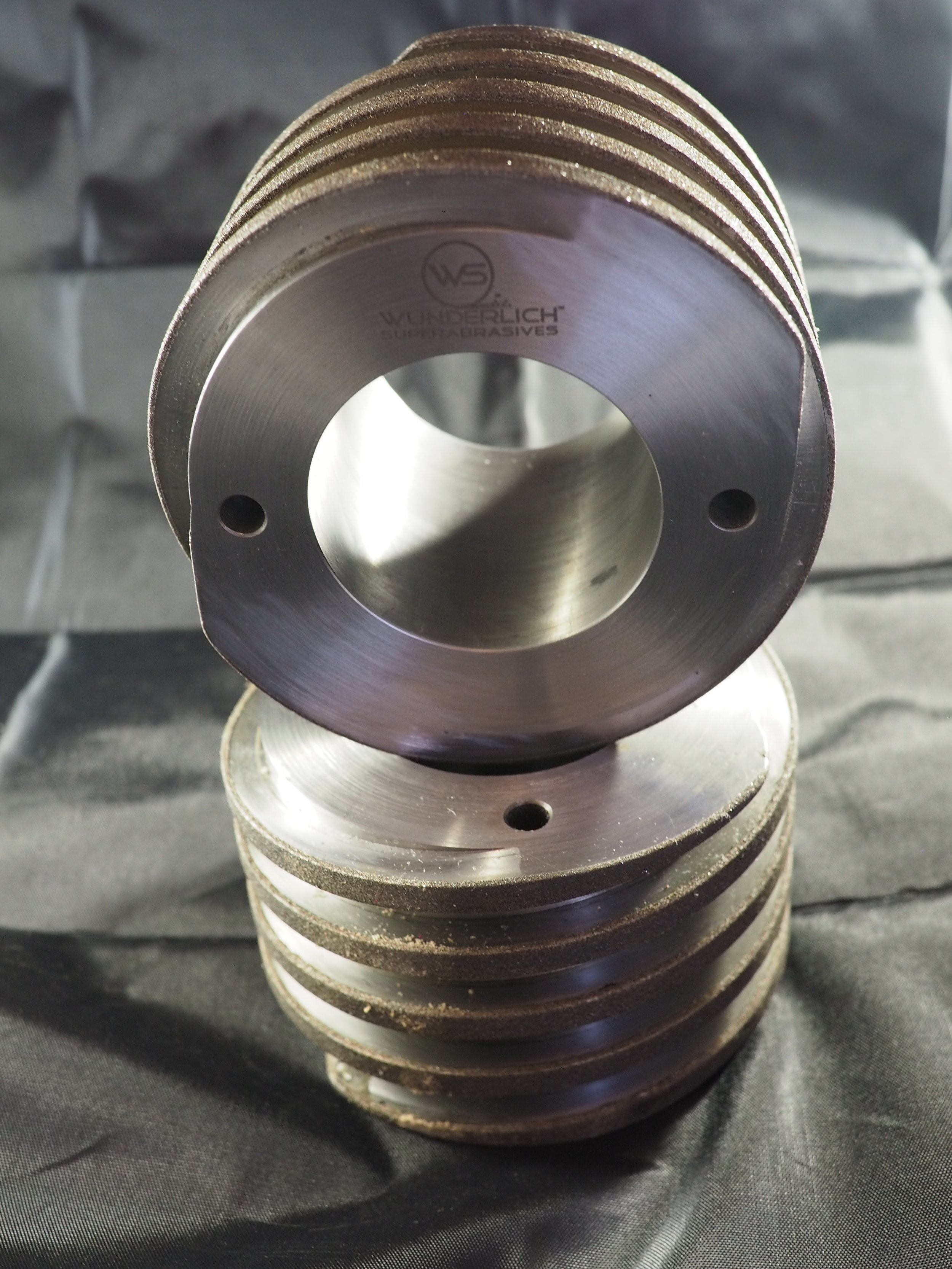

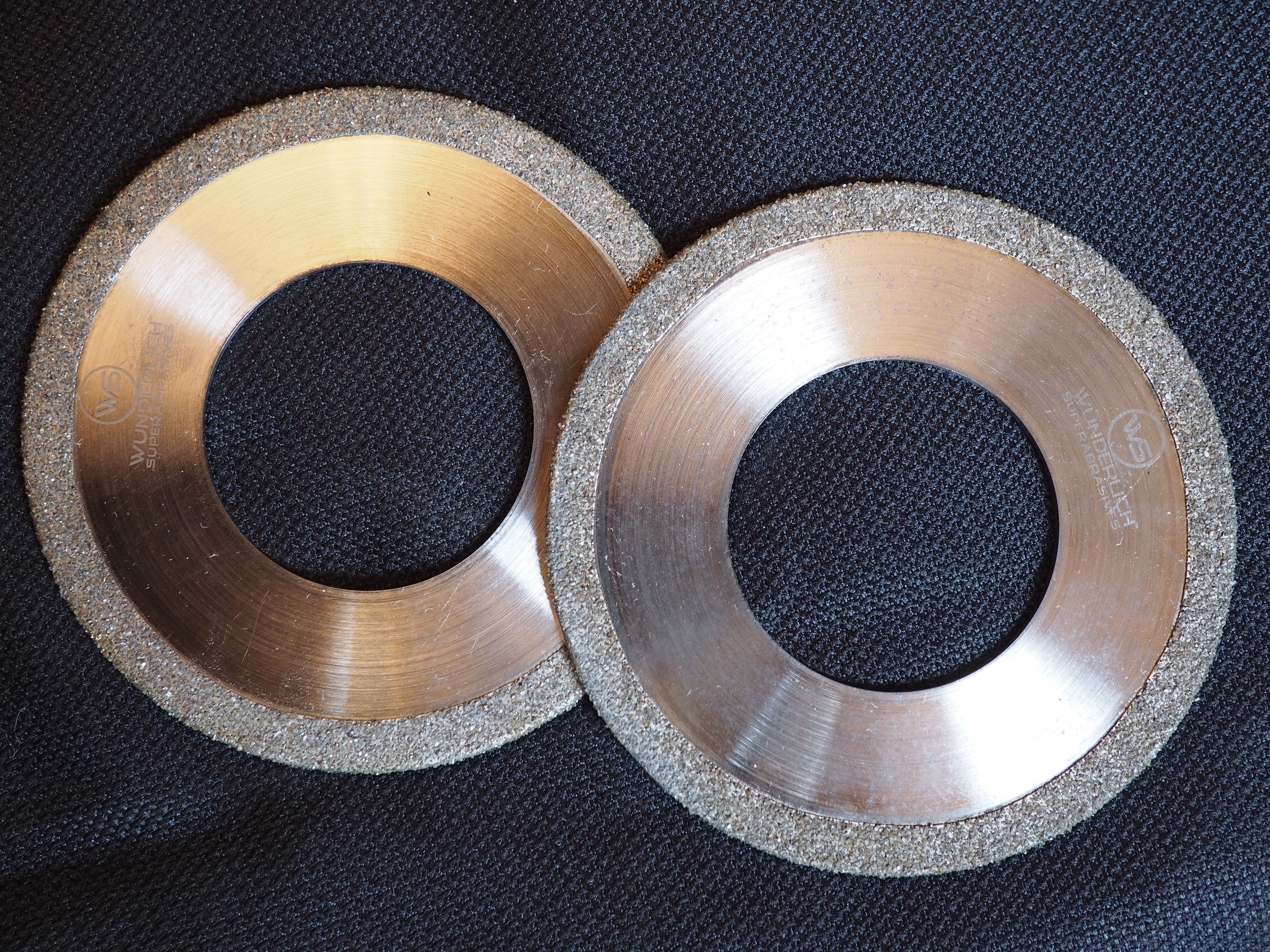

GRINDING WHEELS (Diamond or CBN)

Various Styles up to 30” diameter

Custom Geometries

Dressing or Direct Grinding

Double Disc Grinding

Form Grinding

Thread Grinding

LAPPING PLATES (Diamond or CBN)

Customized for Your Finish Requirements

Various Diameters and Thicknesses

Internal/External Lapping

SAWS (Diamond or CBN)

Various Styles/Geometries up to 30” in diameter

Hole and Core Saws

Slot, Stripe, Pin Hole, Key Hole

Cut-off, Slicing, or Grooving

MANDRELS/hones/PINS (Diamond or CBN)

Custom sizes and geometries

Reamers

Form Grinding (Shank Mounted)

Core Drills

Bull Nose Drills

Bore Finishers/Hones

Jig Grinding

Bottom/Surface Grinding

Expandable Hones

Routers

Carbide Shank

DRESSING TOOLS (Diamond or CBN)

Files

Pads

Dressing Blocks/Rolls

Cluster Dressers

Bars up to 6 feet in length

Strip and Reconditioning

We can recondition your existing tools by stripping the worn out diamond or CBN. Once stripped, we check the integrity of the core and can re-machine it on-site if needed. Saving you time and money is what we are all about!

We understand that success in this industry is based on performance. Being a quality-focused company, we would like to share success with you. Send in your existing tooling done by our competition for a NO COST strip and re-coat so you can evaluate the difference*. *Excludes shipping costs. Substrate geometry must be intact otherwise this will need re-machining, which is not included. Original part sent in cannot change in the previous spec and must include a print.

Electroplating Capabilities

Grit particle sizes from as large as .067” to as small as 3.8 microns

All types and grades of synthetic/natural diamond and CBN

Wheels/Saws up to 30” diameter and up to 1,000lbs in weight

Custom fixtures made for production plating large quantities of mandrels, pins, and files.

Nickel plating on steel for anti-corrosion applications

Precision Machining

We have extensive in-house machining capabilities that let us provide you with quick and cost-effective solutions. We also accommodate full production orders.

Our capabilities include:

CNC Turning - up to 20” diameter

CNC Milling - up to 50” x 25”

CNC Milling with 4th Axis

Manual milling and turning for low-level production

Drilling, tapping, boring, or any machined modifications

Band saw cutting

Surface Grinding

Extensive CAD/CAM capability for designing your project

Magnified optical dimensioning to reverse engineer your tooling requirements

High-Resolution Laser marking and engraving for your logo and/or serial/part numbers